New building featuring state-of-the-art-equipment

500sqm of cutting-edge research and development laboratories, 1,500sqm of advanced production facilities, and 500sqm of modern offices: featuring state-of-the-art equipment, our new facility features whatever it takes to create sustainable and impactful biotech solutions for our partners and customers.

Fermentation units

- Lab-scale fermentation units (2 X 1 L + 4 X 6,5 L)

- 2 X 150 L pilot-scale fermentation units

- 1 X 1,500 L fermentation unit

Downstream technologies

- Disc-stack centrifugation

- High-pressure homogenization

- Tangential flow micro-filtration

- Tangential flow ultra-filtration

- Enzyme immobilization

- Formulation & drying

Analytics

- Ultra-High Performance Liquid Chromatography

- UV-VIS Spectrophotometry

- SDS-PAGE Protein quantification

- YSI biochemistry analyzer

Biosphere’s fermentation facility was designed to satisfy to the diverse needs of research, development, pilot-scale production, and industrial-scale applications.

6 lab-scale fermentation units

2X 1 Liter + 4 X 6.5 LITERS

Our lab-scale fermentation units provide the perfect environment for researchers to conduct controlled experiments, test hypotheses, and fine-tune bioprocesses on a small scale. These units offer precision and flexibility, enabling us to explore a wide range of biotechnological possibilities with ease.

2 pilot-scale fermentation units

2 X 150 LITERS

The pilot-scale fermentation unit is the bridge between laboratory-scale research and full-scale industrial production. It allows us to take promising discoveries from the lab and test their feasibility on a larger scale. Fermentation at this size is a key factor for optimizing processes and ensuring scalability, reducing the gap between proof-of-concept lab scale experiments and full scale industrial applications.

1 industrial-scale fermentation unit

1 X 1.500 LITERS

At the heart of our industrial operations lies our 1,500-liter fermentation unit. This fermentation size represents the culmination of our research and development efforts. It is here that we bring our innovations to industrial scale, producing fully implemented biotechnological solutions.

The production of finished biotechnological products requires precise and sophisticated downstream processing. Our facility is equipped with all key downstream technologies, at laboratory, pilot and industrial scale, allowing us to offer a wide range of capabilities in this critical area ensuring scalability.

Disc-stack centrifugation

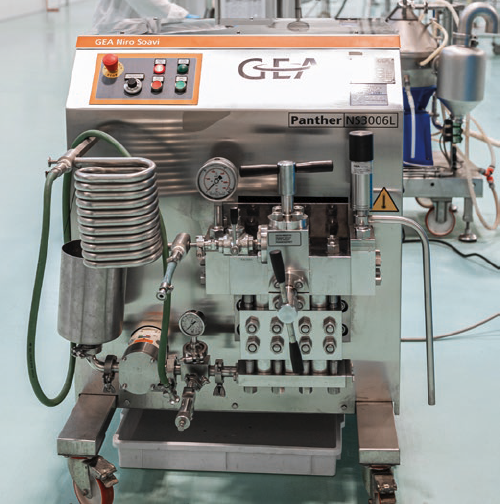

High-pressure homogenization

Tangential flow

micro-filtration

Tangential flow

ultra-filtration

Enzyme

immobilization

Formulation & drying

Disc-stack centrifugation enables us to efficiently separate solids and liquids from fermentation broth or other complex mixtures.

High-pressure homogenization is a key component of our downstream equipment, allowing us to break down cell walls and extract valuable intracellular compounds.

Tangential flow micro-filtration technology allows us to selectively separate and remove particles, contaminants, and unwanted substances from biotechnological solutions. This process is vital the clarification of supernatant solutions from disk-stack centrifugation and allow the performance of the following ultrafiltration steps.

Tangential flow ultra-filtration takes our downstream processing capabilities to the next level. With this technology, we can separate macromolecules such as proteins and enzymes from smaller molecules, resulting in highly purified and concentrated biotechnological products.

Enzyme Immobilization on different support materials can be studied and optimized at laboratory scale, and then scaled-up with a capacity of 100 kg/batch.

Formulation & Drying the customer’s products can be delivered in liquid form or solid formulations using freeze-drying or spray-drying techniques.

Analytics

Our chemical and microbiological laboratories are equipped with analytical technologies for process analytics, quality control and release of final products.

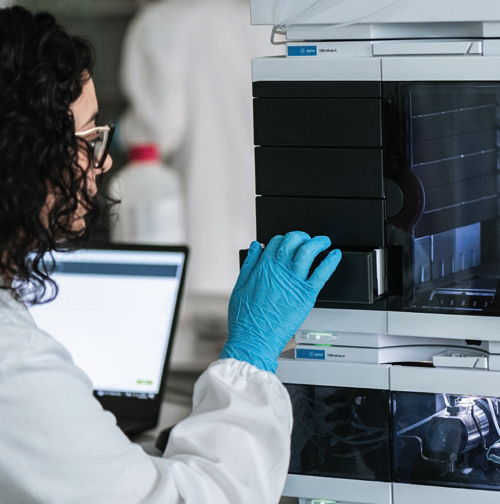

UHPLC

UHPLC guarantees efficient separation and high resolution for the characterization and quantification of cellular metabolites, polymers, small molecules, chiral compounds.

UV-VIS

UV-VIS Spectrophotometry measures the intensity of a light beam at different wavelengths. This technique is essential in biotechnology. It is used to quantify cell density and has a wide application in protein characterization. With temperature-controlled UV-VIS Spectrophotometer, investigation of enzyme activity, protein denaturation, and protein melting point is conducted.

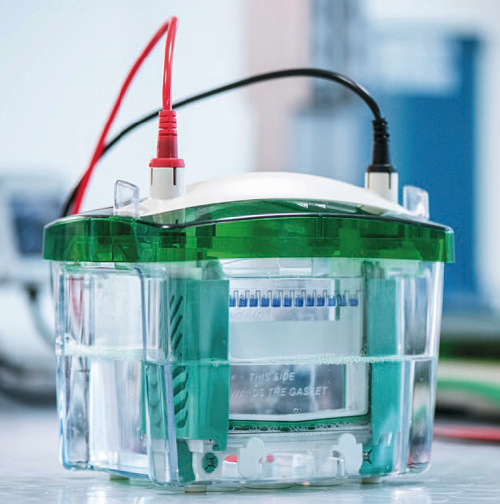

SDS PAGE

This method is fundamental in research and industry for protein analysis and has numerous applications in studying biological processes and developing biotechnological products. SDS-PAGE is based on the molecular weight of proteins and is essential for analyzing protein purity, studying protein-protein interactions, and identifying proteins in complex mixtures when coupled with techniques like Western blotting.